Tyre wear patterns

Just like a picture – your tyre wear tells a story. Tyres develop different wear patterns depending on the forces they are subjected to, and the conditions they are most commonly operating in. Uneven tyre wear can compromise the life and performance of your tyres, the handling of your vehicle, and your safety.

Check out our checklist of what to look for when evaluating premature tyre wear. What is your tyre wear pattern trying to tell you?

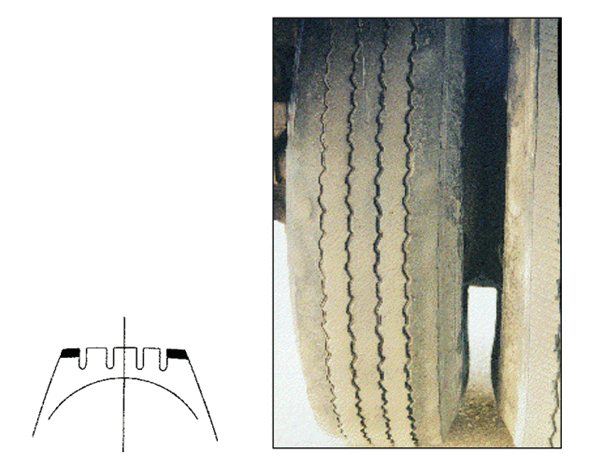

Premature shoulder wear

Here, the shoulders of the tyre will be more worn than the centre due to having excessive contact with the road.

How it happens

- Under inflation

- Worn steering components

- Misalignment

The risks

Under-inflation can lead to tread separation and blowouts. Blowouts can be particularly hazardous as they can cause the driver to lose control of the vehicle and crash, putting other drivers at risk. Improper wheel alignment can result in undue stress on a vehicle’s suspension. When driving at high speeds, wheel misalignment can cause difficulty in steering, increasing the risk of an accident. Overall, premature shoulder wear can reduce tyre life by 15% or more and decrease fuel economy caused by making your engine work harder.

What to do about it

For the best handling and fuel efficiency, keep your tyres pumped to the right tyre pressure according to your manufacturer's optimum tyre pressure recommendations. If you notice your truck vibrating for no apparent reason or tend to veer to the side, it may be suffering misalignment. Take it to the shop as soon as possible.

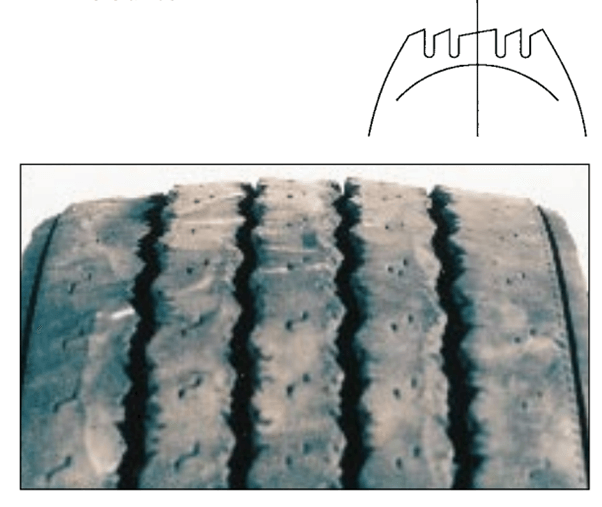

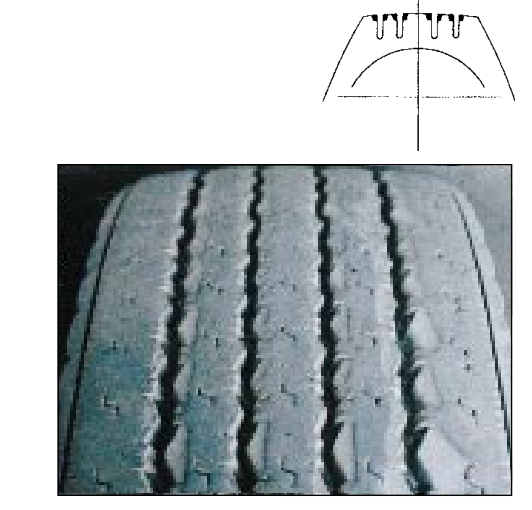

Premature centre wear

Here, the centre of the tyre will be more worn than the shoulders due to having excessive contact with the road.

How it happens

- Over-inflation

- Tyers too wide for rim

The risks

Over-inflation causes loss of traction which leaves you susceptible to crashing. There’s also an increased risk of blowouts due to excessive heat. A rim that is too narrow in relation to the tyre width will allow the tyre to distort excessively sideways under cornering.

What to do about it

Keep your tyres to the recommended inflation pressure specified, according to your manufacturer's optimum tyre pressure recommendations. Also refer to your owner’s manual or the sticker in your door jam. Always ensure your tyres are fitted properly to the rim.

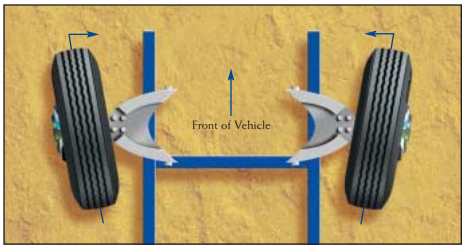

Feathered wear

This is when one side of a tread rib is worn lower than the other side, often due to a combination of improper alignment settings, such as excessive toe and caster. It can be identified by running your hand along the tyre and the tyre feeling smooth one way but rough the other way.

How it happens

- Excessive toe (in or out)

- Worn bushings

- Misalignment

TOE – IN

TOE-OUT

The risks

Your ability to steer the vehicle is compromised and the ability for the type to grip wears away, meaning your truck can easily become unsafe on a straight, during cornering and/or under braking. This is especially concerning if/when the driver must respond swiftly and change course in an emergency.

What to do about it

Alignment should be checked every 10,000 km or 6 months, whichever occurs first, unless you know that you have hit a pothole, or another object, in which case it should be done immediately as a precaution.

One side wear

Also known as camber wear, this is when one shoulder or side of the tyre is worn more than the other because it is taking a heavier amount of the load.

How it happens

- Incorrect camber settings

- Worn joints

- Worn k/pin bushes

POSITIVE CAMBER

NEGATIVE CAMBER

The risks

There is a danger the worn joint may break or pull apart causing loss of steering control.

What to do about it

On high-mileage vehicles, replacing all the joints at the same time is recommended if one or more joints are worn beyond specifications. Ensure regular truck maintenance to ensure vehicle handling, comfort and fuel consumption is optimised.

Scalloping/cupping

This is erratic dips or depressions appearing around the edge of the tread caused by excessive tyre bouncing or wobbling.

How it happens

- Worn or bent suspension parts including faulty shock absorbers

- Wheel and tyre out of balance condition

- Tyre flat spots (brake lock-up)

The risks

Unbalanced wheels produce a vibration that is uncomfortable to drive in and negatively affects the handling of the vehicle. Placing stress on suspension and steering components can lead to potential crashes and expensive repairs.

What to do about it

Take your truck to a truck workshop for further investigation immediately.

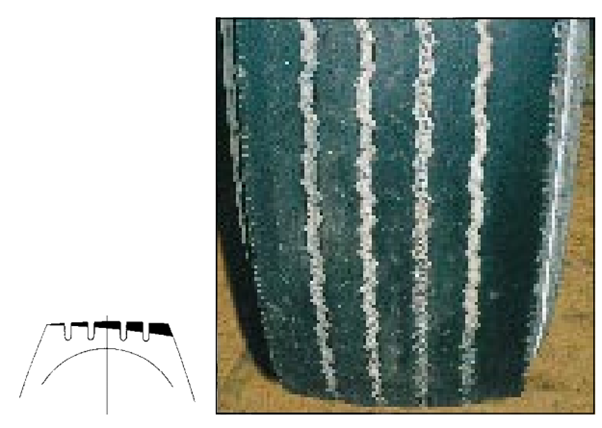

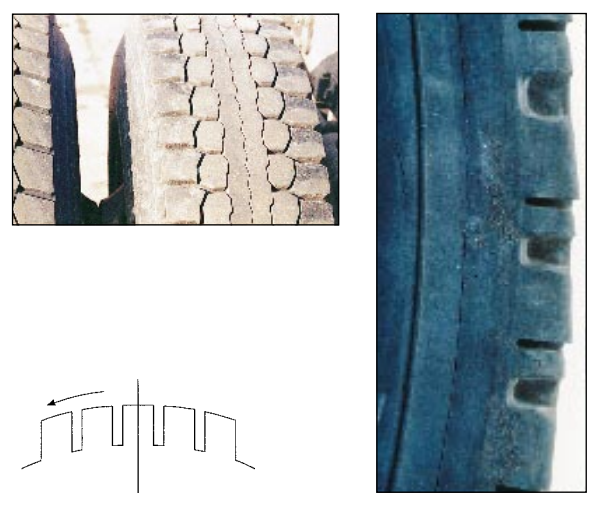

Heel and toe wear-drive tyres

Front edges of tread blocks are higher or lower than rear edges due to tread blocks distorting or not making full contact with the road. It looks like feathering, only the ramps run front-to-back along the tyre rather than side-to-side. The leading edge of the tread blocks will be worn smooth while the trailing edge will be sharp.

How it happens

- Mismatched duals

- Variance in pressure between duals

- Torque stress

- Tread/tyre design

The risks

Mismatched duals encourage irregular wear and increases the risk of blowout. Damage incurred through mismatching dual tyres can cost fleets as much as 20% in tread life.

What to do about it

Heel-toe wear is typically a symptom of insufficient tyre rotation and maintenance intervals, so keep up with your truck’s maintenance schedule.

Alternative lug wear

Tyres have inconsistent tread block wear, up and down caused by tyre not making uniform contact with the road.

How it happens

- Mismatched duals

- Variance in pressure between duals

- Poor suspension control

The risks

Driving with worn suspension control and shock absorbers can fatal, with as much as 20% added to your stopping distance and increased risk of skidding on wet roads.

What to do about it

Get your shocks and suspension system checked every 20,000km by a qualified mechanic or when your truck starts to skid a bit more or take longer to brake.

Erosion wear

Circumferential wear along rim edges as a result of slow wear rate of radial tyres on free rolling axles.

How it happens

- Very little rubber being shaved

- Not maintenance related, simply a function of long-life

- Should not be of concern

The risks

None! This is healthy wear and tear of tyres.

What to do about it

Feel good that you don’t have a tyre issue.

TIP: It's important to ensure your tyres are cold before you check the tyre pressure.

Keep yourself covered in case you ever have a tyre problem while out on the road. Truck Assist’s Roadside Assistance package helps take the pressure off when things go wrong. With a network of suppliers and skilled technicians include the best heavy truck operators in the country, Truck Assist provides national assistance 24/7, 365 days a year.